Sleep-Mode for Beverage Coolers and Vending Machines

Definition

Smart controls, also called energy management systems or devices, are integrated in beverage coolers and vending machines. They learn the opening hours of the shop where they are located and put the cabinet into sleep-mode in the off-hours. The cooler automatically switches back on in time to pull down beverage temperatures for the coming day, or it gets triggered to switch back on by the first door opening.

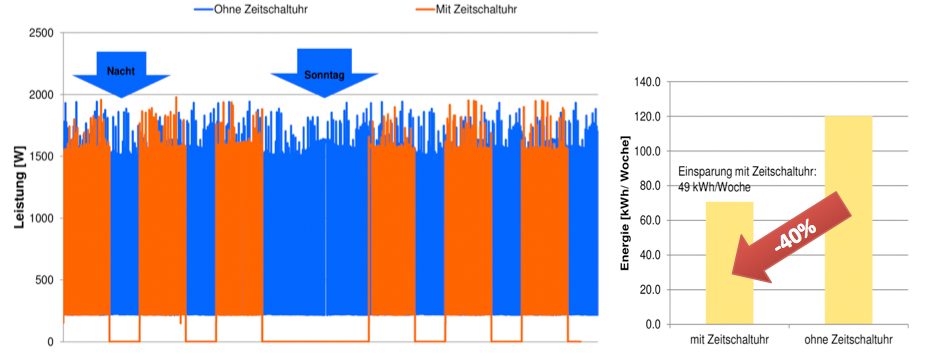

Field measurement in Switzerland shows 40% reduction in energy costs

A beverage cooler in a canteen was measured in December 2014 (data was provided to Topten by the operator of the canteen anonymously). The measurement showed that energy consumption can be reduced from 120 kWh per week to 71 kWh per week when the cooler is shut off over night and on Sunday.

Examples of smart controls

The following control devices allow smart energy management according to the manufacturers. The products were not tested or evaluated by Topten. Therefore the list is not a recommendation. Contact us if your company offers similar products.

- Danfoss ERC 112: http://products.danfoss.com/productrange/documents/refrigeration/electronic-controls/electronic-refrigeration-temperature-controls/erc-ekc-electronic-refrigeration-controls/erc-112/

- Eliwell EWPlus 974: http://www.eliwell.it/product.aspx?id=13851&LangType=2057

Manufacturers that offer beverage coolers with smart controls

Pretty much every cooler can be equipped with a smart control. The following manufacturers have already done it:

- Frigoglass

- Klimasan

- Liebherr

- Ugur

- and many more... (contact us if your company does!)

Beverage companies that already use smart controls

- Coca-Cola

- Heineken

- and many more... (contact us if your company does!)

Smart controls are second-best improvement option after using merchandisers with doors

The European Commission Joint Research Centre (JRC), in its preparatory study update report on commercial refrigeration, says that smart controls are the second most effective improvement option to achieve energy savings in beverage coolers and vending machines. The saving potential is estimated to be 26% on average and up to 45% in the best case. The first most effective improvement option is using merchandisers with doors instead of open cabinets (yielding a reduction in energy costs by 40 – 50% according to JRC’s report).

Quote from JRC’s report: “Smart sensors/energy management devices (...) can reduce the energy consumption up to 45% by allowing the temperature inside the cooler to rise (between 7°C to 14°C) during periods when the outlet is closed or rarely used, and by maintaining the working temperature (between 0°C and 7°C) during the active hours. This is only applicable to can/bottle machines with no food safety temperature requirements. For perishable items like sandwiches, the temperature cannot rise above 10°C for more than half an hour. For such machines, only controlling energy-consuming components that do not affect the working temperature could save energy, like switching off lights, or reducing the speed/power of compressor and fans.” (5.5.4 Electronic control, p. 54)

However, some beverage companies made the experience that energy savings through EMD are lower, namly 15% on average and up to 25% in the best case (based on 12 hours business-mode and 12 hours standby-mode per day, with a pull-down-phase of maximum 3 hours before business-mode).

References

- Ecodesign for Commercial Refrigeration, Preparatory study update published report, August 2014 by the European Commission Joint Research Centre (JRC).

- Download the ProCold factsheet on smart controls

Contact: pro-cold (at) topten.eu

06/2015 Geilinger

Back to the ProCold project main page

ProCold is an EU-project aiming to improve energy efficiency in plug-in refrigeration equipment and speed up the switch to climate-friendly refrigerants. Objectives of the project:

- Showcasing best products

- Supporting green procurement

- Helping to implement effective policies